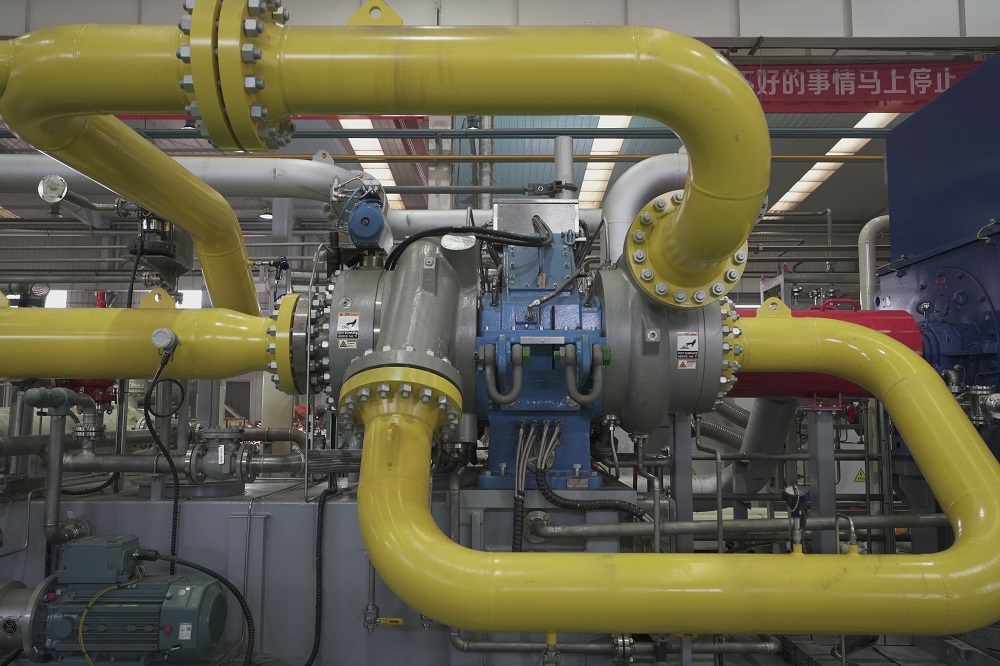

The reciprocating compressor package designed and manufactured by Jereh has a maximum power of 7457kW and a maximum exhaust pressure of 62 MPa. The customized product design better meets your actual on-site working condition.

Partners:

Advantages:

-

Extremely complex conditions, stable and reliable performance;High power(4000KW and above), mature application; -60℃~55℃ Run smoothly.

-

Extensive experience, a lot of overseas project reference; Global project reference 1000+; Familiar with global standards

-

Low energy consumption, low operating cost: 1~3%More Efficiency for Ariel compressor; Simple cylinder structure, high volumetric efficiency.

-

Long life, cover less area: 25 years warranty for unit, 6 years warranty for the key parts; The compressor is smaller in size and has no water-cooling system of cylinder liners.

-

Advanced technology, low failure rate: Force feed lubrication system, Divider valves distribution block lubrication; Compressor crankshaft driven oil pump through sprocket, Compact and simple structure.

Application:

-

Gas Gathering and Boosting

-

Fuel Gas Boosting

-

Gas Recycle

-

Gas Storage

-

Acid Gas Injection

-

Hydrocarbon Recovery

-

LNG Liquefaction Plant

-

CNG Fueling Station

And:

Refrigerant compressor, chemical process gas compressor and other specialized gas boosting such as CO2/H2/N2 etc.

Specific working environment such as offshore platform, onshore CPF/EPF, Chemical Plant etc.)

Stable operation under high ambient temperature and high H2S conditions.

High pressure, high flow rate, CE certified package.

Stable operation under ambient temperature from -60℃ to 36℃

Safe operation under 85% H2S condition.

Offshore platform application, highly compact and minimized vibration & pulsation design.