Yantai/ April 22, a live acceptance test on Jereh offshore compressor packages was organized in Jereh Headquarters.

The client, who is from Indonesia, couldn’t come to China in person due to the ongoing COVID-19 outbreak. Therefore, Jereh took the advantage of live-streaming technology to broadcast the test process.

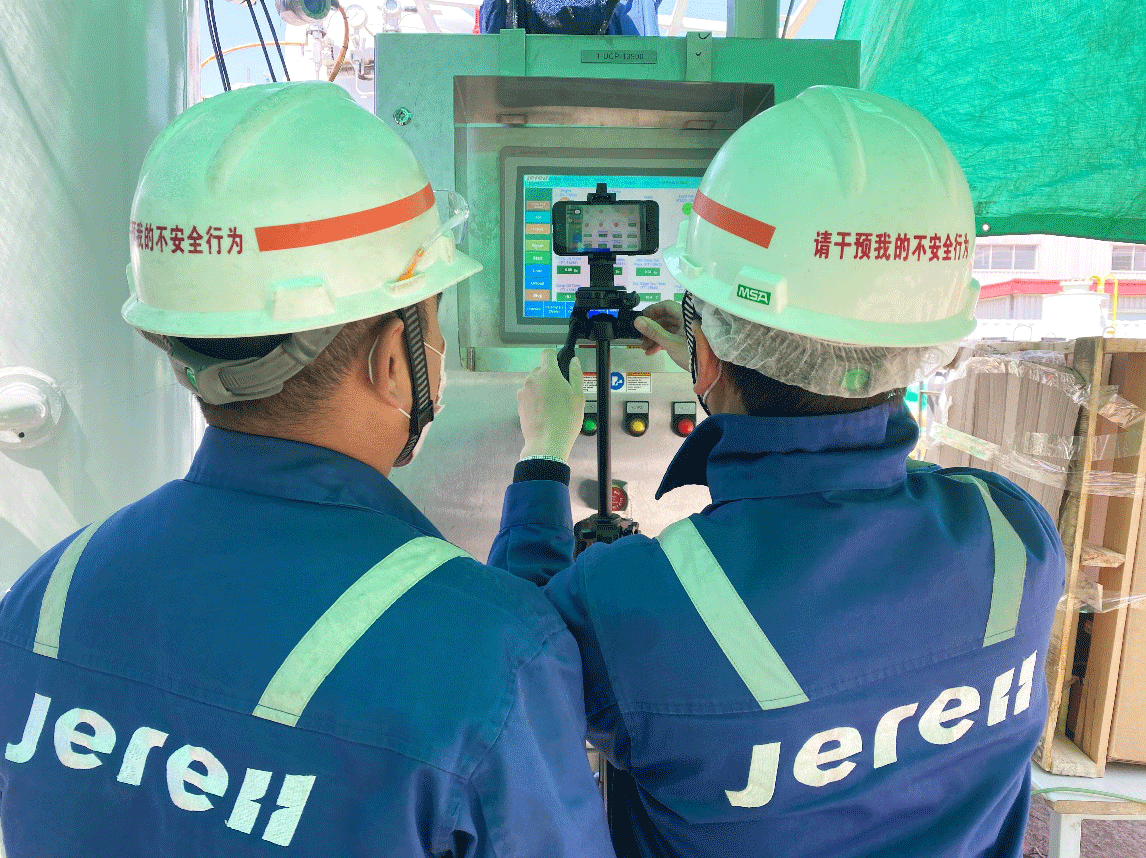

Figure 1: A live acceptance test on Jereh offshore compressor packages was organized.

Jereh won this offshore compressor project last September, and Jereh’s engine-driven compressor packages will be used for the re-development of an 8 MMscfd low-pressure well.

It is worth noting that compressor packages for offshore platform usually require high vibration absorption, strong explosive-proof ability and high integration. Moreover, the project should meet both Total standard and PERTAMINA standard.

To guarantee on-time delivery of the project, Jereh speeded up logistics ahead of time in late January when COVID-19 began to break out in China. As a result, they avoided the impacts of supply shortage as well as transportation shutdown, and managed to keep up with production schedule. After resuming operation in mid-February, Jereh has been gradually enhancing production efficiency, thus accomplishing the project on schedule.

For the live test, Jereh staff from R&D, sales and test departments worked closely to prepare for over 400 tests such as electronic tests, mechanic test and so forth. Multiple devices were set on the site to display the performance in an all-around way.

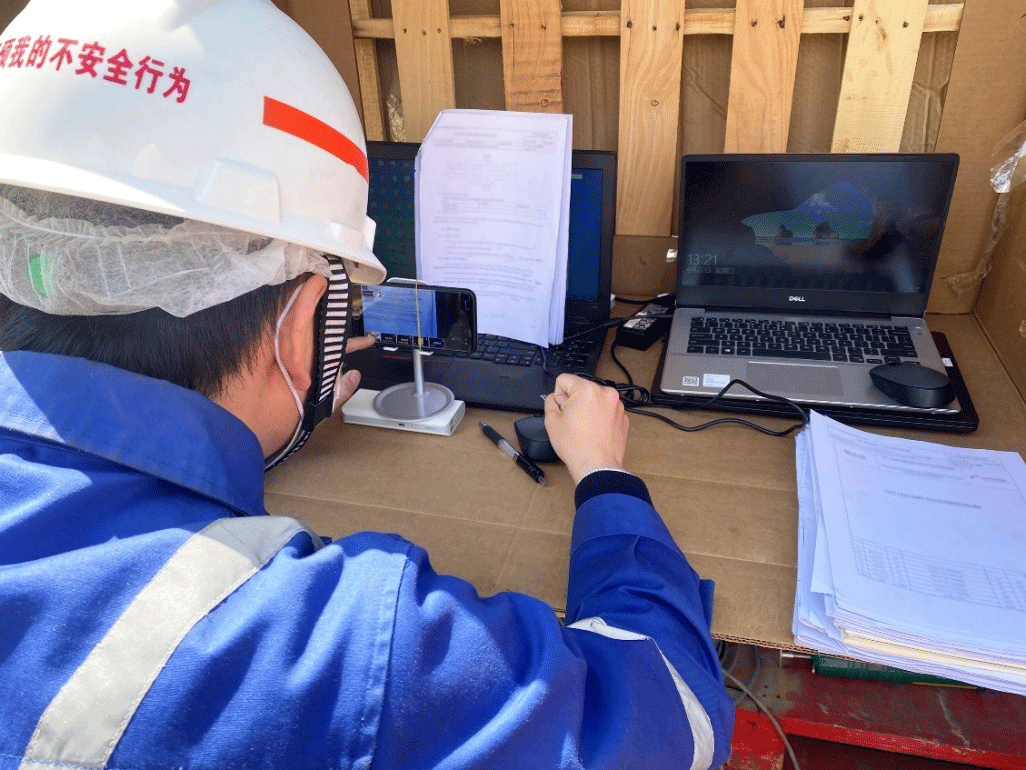

Figure 2: Jereh staff from R&D, sales and test departments worked together to prepare for factory acceptance test

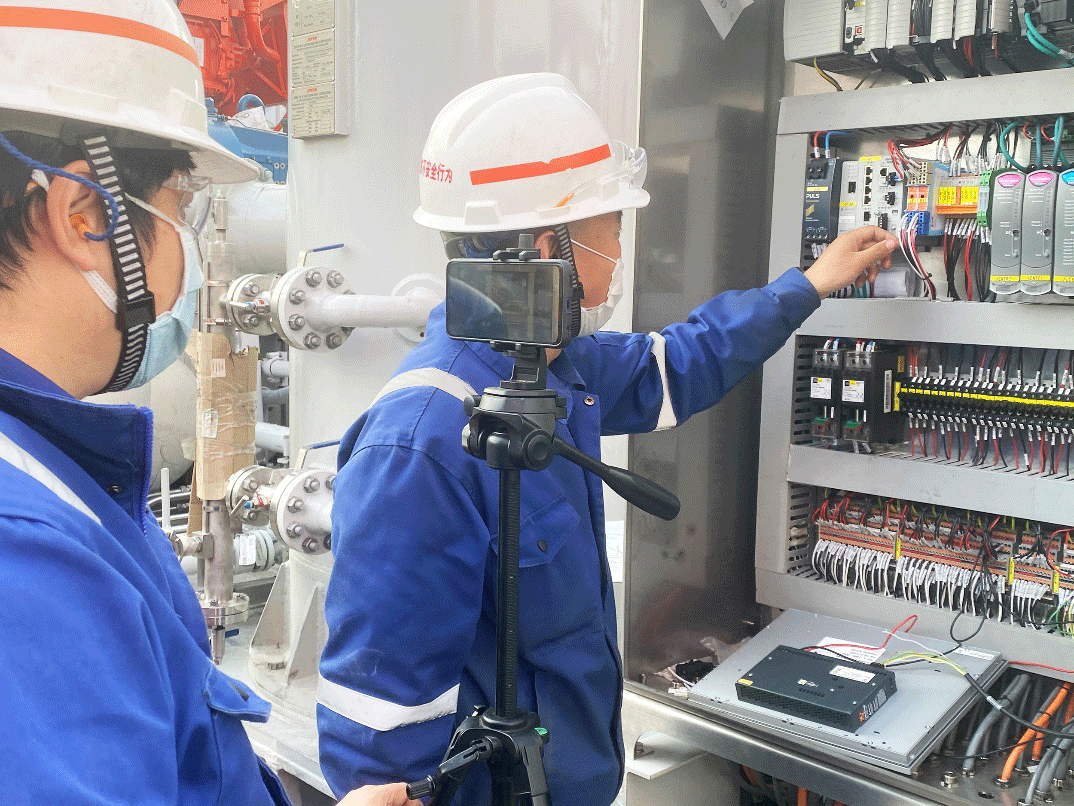

After 10-hour live test and online Q&A, the highly-integrated skid-style offshore engine-driven compressor packages passed the acceptance test successfully. The client comments, “The live test turns out very effective and we are deeply impressed by Jereh engineers and their professional, detailed explanation.”

“We are also surprised to see that Jereh can deliver the project on time with high quality although they were facing COVID-19. It perfectly manifests Jereh’s speed and China’s speed as well.”

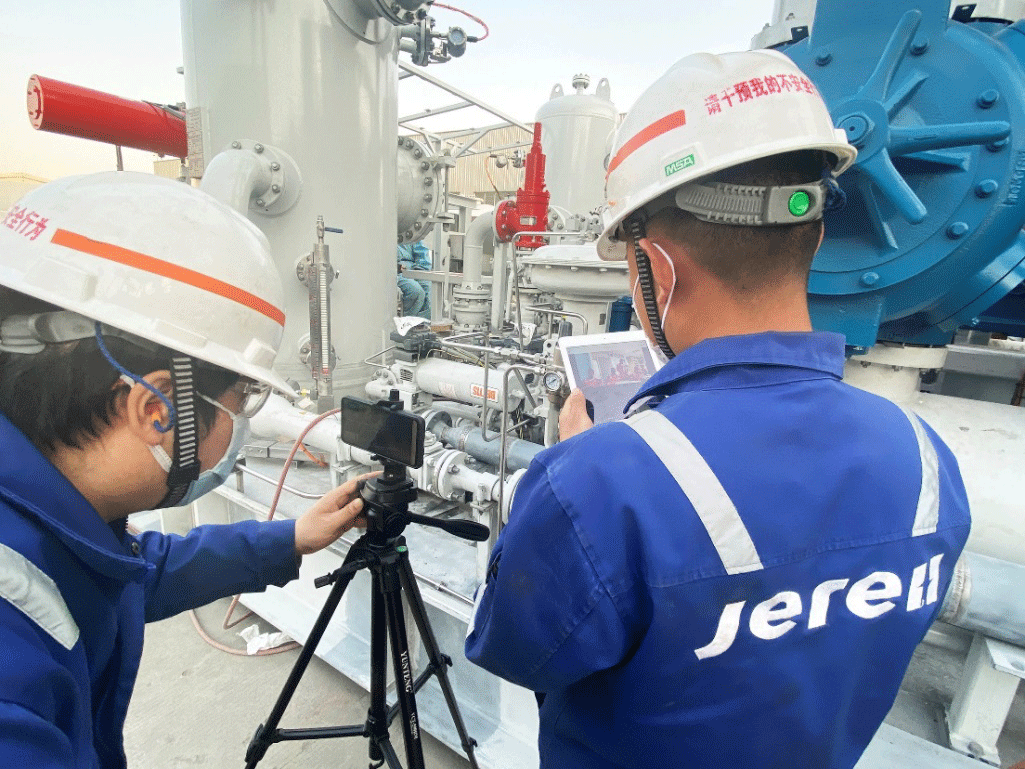

Figure 3: The live test and online Q&A took 10 hours.

The project manager says, “The client cares technology process, compact skid and integration. Therefore, we optimized design and showed the supporting and pipeline system during the live test. The design dramatically reduce weight and room occupation while satisfying technology process.

During the test, we conducted dynamic analysis to verify running status and collect monitoring data, through which we can see how effective the design is in terms of vibration attenuation. Besides, our customized design that is with no high voltage, no independent airflow for instrument, no independent fuel gas, etc. were displayed to our clients too.”

Figure 4: The live test turns out very effective and received positive feedback from client.

After the acceptance test, Jereh will set about preparing for compressor delivery and sending out a team to the project site for installation and commissioning.